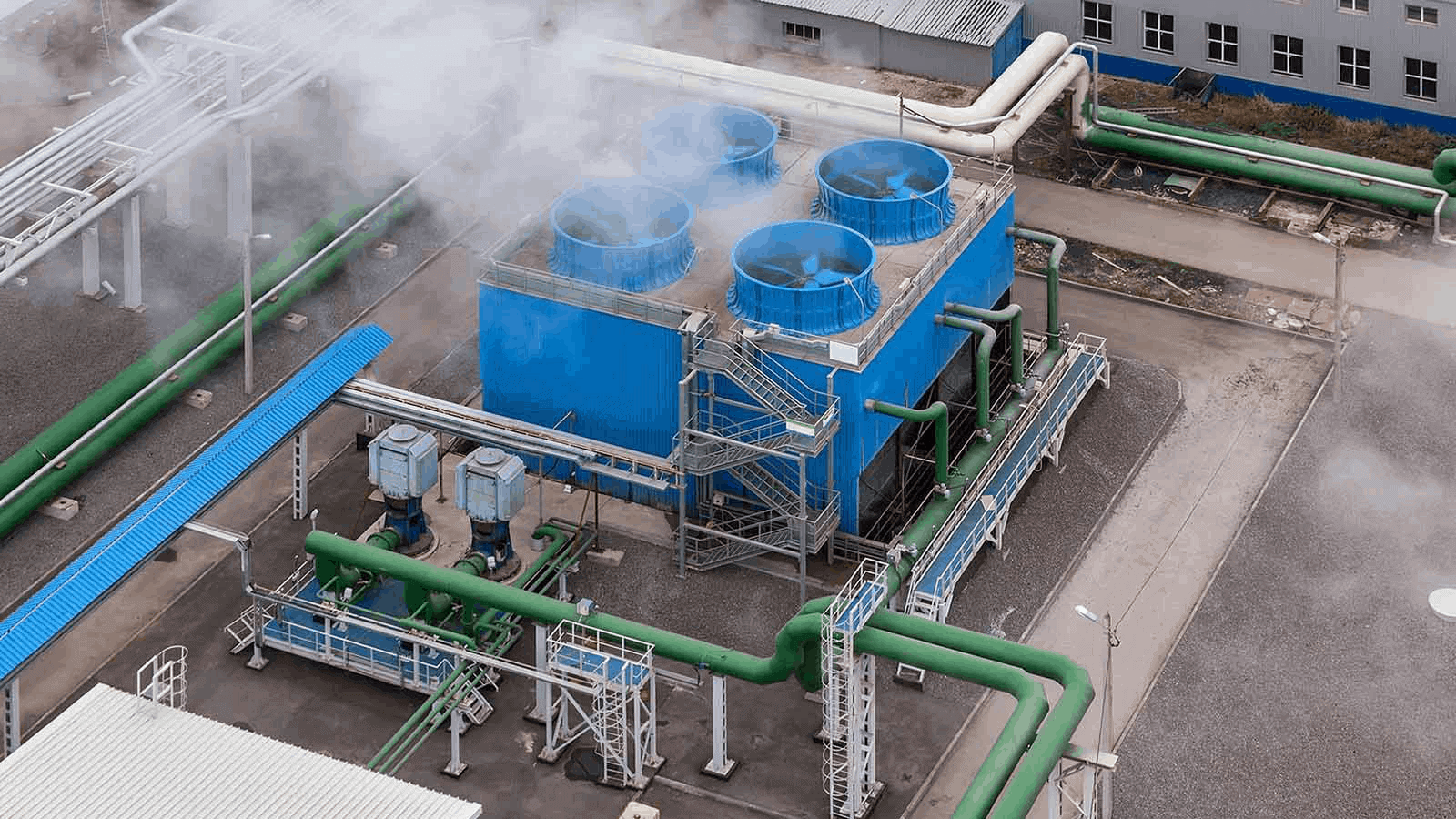

What Is A Cooling Tower?

A cooling tower is a specialized heat exchanger in which air and water are brought into direct contact with each other in order to reduce the water’s temperature. As this occurs, a small volume of water is evaporated, reducing the temperature of the water being circulated through the tower.

Water, which has been heated by an industrial process or in an air-conditioning condenser, is pumped to the cooling tower through pipes. The water sprays through nozzles onto banks of material called “fill,” which slows the flow of water through the cooling tower, and exposes as much water surface area as possible for maximum air-water contact. As the water flows through the cooling tower, it is exposed to air, which is being pulled through the tower by the electric motor-driven fan.

When the water and air meet, a small amount of water is evaporated, creating a cooling action. The cooled water is then pumped back to the condenser or process equipment where it absorbs heat. It will then be pumped back to the cooling tower to be cooled once again. Cooling Tower Fundamentals provides a level of basic cooling tower knowledge and is a great resource for those wanting to learn more.

Types Of Cooling Towers

Crossflow Cooling Towers

In crossflow cooling towers the water flows vertically through the fill while the air flows horizontally, across the flow of the falling water.

Because of this, air does not have to pass through the distribution system, permitting the use of gravity flow hot water distribution basins mounted at the top of the unit above the fill.

These basins are universally applied on all crossflow towers.

Counterflow Cooling Towers

Counterflow cooling towers are designed so that air flows vertically upward, counter to the flow of falling water in the fill.

Because of this vertical airflow, it is not possible to use the open, gravity-flow basins typical in crossflow designs. Instead, counterflow towers use pressurized, pipe-type spray systems to spray water onto the top of the fill.

Since air must be able to pass through the spray system, the pipes and nozzles must be farther apart so as not to restrict airflow.

Induced Draft vs. Forced Draft Cooling Towers

Factory-assembled towers (FAP) are built and shipped in as few sections as the mode of transportation will permit. A relatively small tower will ship essentially intact. A larger, multi-cell cooling tower is manufactured as modules at the factory, and shipped ready for final assembly. Factory-assembled towers are also known as “packaged” or “FAP” (factory-assembled product). Factory-assembled cooling towers can be crossflow or counterflow, induced draft or forced draft, depending on the application. While all applications are different, the factory-assembled Marley NC crossflow, induced draft tower is widely used for HVAC and light industrial applications.

Field-erected cooling towers (FEP) Field-erected towers are primarily constructed at the site of ultimate use. All large cooling towers, and many of the smaller towers, are prefabricated, piece-marked, and shipped to the site for final assembly. The manufacturer usually provides labor and supervision for final assembly. Field-erected towers can be crossflow or counterflow, depending on the application. For power and heavy industrial applications, the field-erected Marley F400 counterflow tower can be customized to meet your exact specifications for performance, structure, drift and plume abatement.

Using a total system approach, every cooling tower and component is designed and engineered to work together as an integrated system for efficient performance and long life.

HVAC Free Cooling – A free cooling system allows the tower to directly satisfy a building’s cooling needs without the need of operating the chiller in cold weather. The goal of a free cooling system is to save energy. There are specific types of free cooling systems and certain elements that must be in place for a free cooling system to be considered.

Variable Flow – There may be significant energy savings opportunities if the cooling tower can be operated under variable flow in off-peak conditions. Variable flow is a way to maximize the effectiveness of the installed tower capacity for whatever flow the process has.

OEM parts – Precision-engineered to provide a reliable product, Marley OEM parts are built to the highest standards and tightest tolerances for extended service life.

Geareducer® Solutions – Gearboxes are available in a variety of designs and reduction ratios to accommodate the different fan speeds and horsepowers of cooling towers. The Marley Geareducer Solutions program lets customers order a new replacement gearbox for a tower from SPX, or a factory-trained technician can repair an existing gearbox or rebuild a gearbox using Marley OEM parts.

Fill – One of the single most important components of a cooling tower is the fill. Its ability to promote both the maximum contact surface and the maximum contact time between air and water determines the efficiency of the cooling tower. The two basic fill classifications are splash type fill (breaks up the water) and film type fill (spreads the water into a thin layer).

Drift eliminators – Designed to remove water droplets from the discharged air and reduce loss of process water, drift eliminators cause the air and droplets to make sudden changes in direction. This causes the drops of water to be separated from the air and deposited back into the tower.

Nozzles – Crossflow configuration permits the use of a gravity-flow distribution system with a nozzle such as the Marley ST. With this system, the supply water is elevated to hot water distribution basins above the fill and then flows over the fill (by gravity) through nozzles located in the distribution basin floor. Counterflow configuration necessitates the use of a pressure type system of closed pipe and spray nozzles like the Marley NS.

Fans – Cooling tower fans must move large volumes of air efficiently, and with minimum vibration. The materials of manufacture must not only be compatible with their design, but must also be capable of withstanding the corrosive effects of the environment in which the fans are required to operate. The Marley Ultra Quiet fan is an example of a fan that can be used in situations where very low sound is a necessity.

Driveshafts – The driveshaft transmits power from the output shaft of the motor to the input shaft of the Geareducer. Because the driveshaft operates within the tower, it must be highly corrosion resistant. Turning at full motor speed, it must be well balanced and capable of being re-balanced. Due to the rigorous cooling tower specification requirements, the Marley Comp-DS carbon-fiber driveshaft was designed.

Armstrong Pumps

Armstrong Pumps Bell & Gossett

Bell & Gossett Taco Pumps

Taco Pumps Goulds Water Technology

Goulds Water Technology Grundfos Pumps

Grundfos Pumps Wilo & Scot Pumps

Wilo & Scot Pumps Boilermag XT magnetic filter

Boilermag XT magnetic filter Hoffman Specialty

Hoffman Specialty John Crane

John Crane McDonnell & Miller

McDonnell & Miller Heat Exchangers

Heat Exchangers B&G Power Packs

B&G Power Packs Weg Motors

Weg Motors TechTop Motors

TechTop Motors US Motors & Nidec

US Motors & Nidec Baldor Motors

Baldor Motors SKF Motor Bearings

SKF Motor Bearings Motor Repairs

Motor Repairs