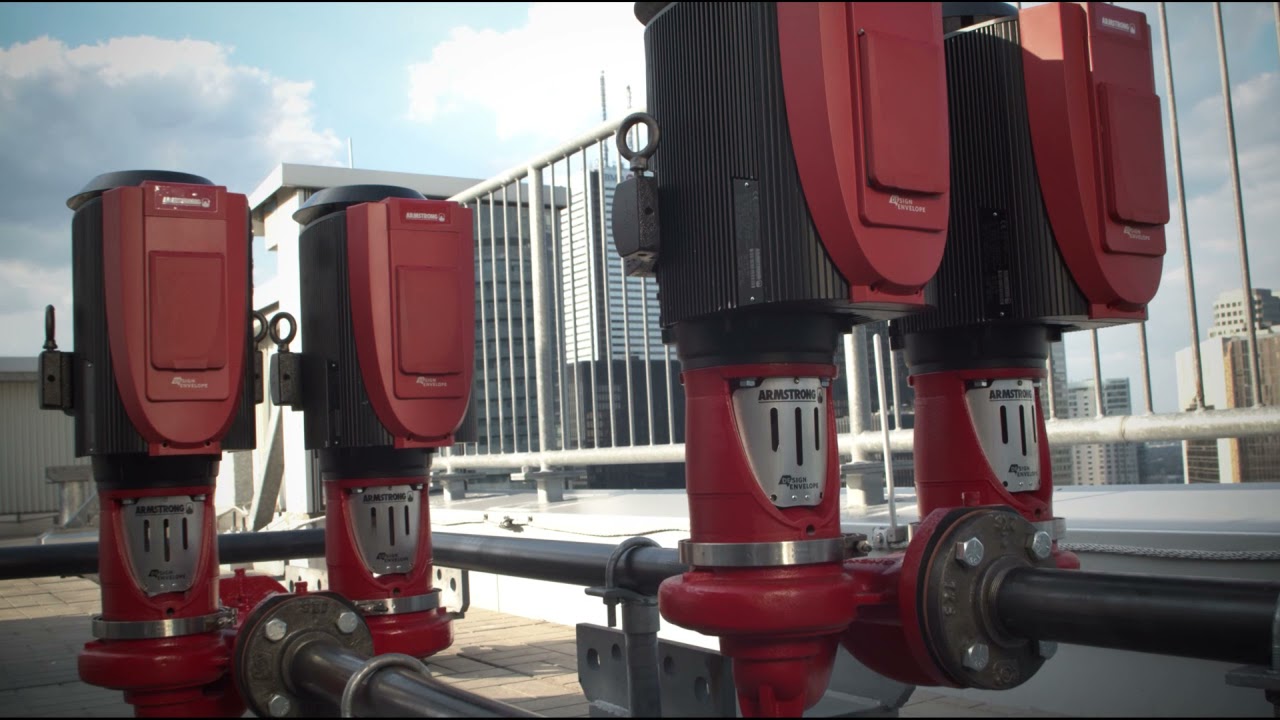

Let’s Talk About Armstrong 4300 Split Coupled Pumps

Armstrong Series 4300 Split Coupled Vertical In-Line Pumps. Armstrong’s vertical in line pumps is a design innovation that continues to lead the industry. Armstrong has improved the efficiency and utility of commercial pumps on a large scale by designing the vertical in line pump in the early 1970s.

Role in Inspiring Engineers

Armstrong continues to play a leading role in educating engineers and inspiring them all around the world on the value of Vertical in line Installations and offers a wide range of sizes and options. Armstrong vertical in line pumps combine it’s excellent operating efficiency with very low vibration. In installations in all around the world, substituting vertical in line pumps has led to significant cost savings in piping and system efficiency on a large scale.

Phenomenal design features

- It has a radially split volute with discharge flange sizes and equal suction.

- Its motor shaft run out is limited to 0.0001 TR.

- Its industry standard motor is designed for vertical in line operation.

- It consists of a dynamically balanced impeller which assures smooth and vibration free operation.

- The grand plate has a flush connection which ensures positive venting of seal chamber and liquid at seal faces.

- It has a heavy cylindrical bracket with 360 degree providing a rigid union of pump and motor.

- Its axially split, spacer type rigid coupling permits seal maintenance without disturbing the pump.

- It has a ribs cast integral with a volute.

- It’s confined casing gasket is designed to meet the stringent industrial temperature and pressure.

- The coupling guard fully encloses access openings.

- 1. It requires a smaller footprint than that of horizontal pumps.

- 2. It is suitable for spaces where the ground area surface is restricted.

- 3. With a vertical centrifugal pump, the NPSH Available can be increased.

- 4. Such pumps are suitable for higher temperature and high pressure fluids.

- 5. Armstrong vertical in line pumps combine excellent operating efficiency with very low vibration and noise.

- 6. It offers a very valuable design/ program whereby an internal designer will work with contractors and engineers to ‘lay out’ and mechanical room using vertical technology.

- Low installation costs

- 1.Vertical in line design eliminates the need for inertia, housekeeping pads, flex connectors and field align mentor grouting requirements.

- 2.Vertical in line design minimizes space and pipe requirements.

- 3.Isolated mechanical seal design with optional sediment filters or separators available to extend seal life in contaminated systems.

- Low energy consumption and operating cost

- 1. Armstrong Series 4300 Split coupled Vertical In line pumps are available with high efficiency motors for significant reduction in energy consumption and cost.

- 2. All motors are suitable for inverter fed service

- 3. Vertical in line design minimizes pipe requirements and related friction losses resulting in higher system efficiency

- 4. Split coupling allows replacement of mechanical seal without disturbing the pump.

- 5. No lubrication or seal adjustments required.

- Low operating risk

- 1. Universal replacement seals, bearing and motors available locally worldwide.

- 2. Optional isolated mechanical seal with sediment filters or separators for extended seal life in contaminated systems.

- 3. Vertical in line configuration allows for less disrupting pump service.

Vertical in line pumps being integral components of the pipework, eliminate need of inertia bases, inertia based springs, flexible pipe connectors, filed grouting and alignment.

Armstrong Pumps

Armstrong Pumps Bell & Gossett

Bell & Gossett Taco Pumps

Taco Pumps Goulds Water Technology

Goulds Water Technology Grundfos Pumps

Grundfos Pumps Wilo & Scot Pumps

Wilo & Scot Pumps Boilermag XT magnetic filter

Boilermag XT magnetic filter Hoffman Specialty

Hoffman Specialty John Crane

John Crane McDonnell & Miller

McDonnell & Miller Heat Exchangers

Heat Exchangers B&G Power Packs

B&G Power Packs Weg Motors

Weg Motors TechTop Motors

TechTop Motors US Motors & Nidec

US Motors & Nidec Baldor Motors

Baldor Motors SKF Motor Bearings

SKF Motor Bearings Motor Repairs

Motor Repairs