Coupled Pump Repairs: A Comprehensive Guide

Split coupled pumps play a crucial role in numerous industrial applications, providing efficient fluid transfer in a wide range of processes. However, like any mechanical equipment, they can encounter issues over time due to wear and tear, improper maintenance, or operational stresses. Understanding the intricacies of split coupled pump repairs can save organizations significant downtime and costs. In this blog post, we will explore the common problems with split coupled pumps, effective repair strategies, and preventative maintenance tips.

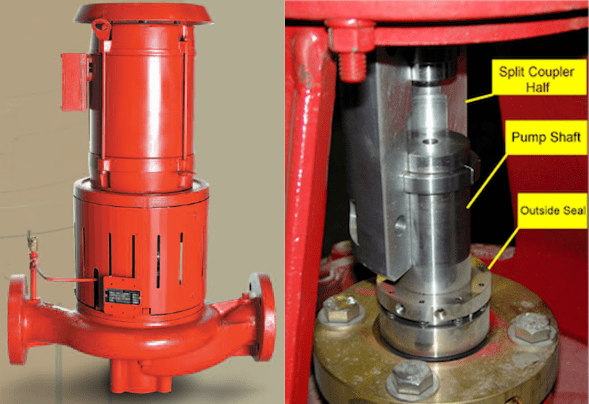

What is a Split Coupled Pump?

A split coupled pump consists of a motor and pump that are connected by a coupling, making it easy to separate them for maintenance and repairs. This design allows for easier access to components without the need for extensive disassembly, which is a significant advantage when servicing the pump.

Common Issues with Split Coupled Pumps

- Coupling Misalignment: Over time, couplings can become misaligned, leading to vibrations and increased wear on bearings and seals.

- Worn Bearings: Bearings support the pump shaft, and over time they can wear out, leading to increased noise and potential shaft damage.

- Seal Leaks: Seals can wear down due to changes in temperature and pressure, leading to leaks that can contaminate the surrounding environment.

- Pump Cavitation: Operating a pump at low levels can cause cavitation, leading to potential damage over time due to the formation and collapse of vapor bubbles.

- Blockages: Foreign materials can enter the pump, causing blockages that impede fluid movement and increase operating pressure.

Repair Strategies

When a split coupled pump shows signs of failure, it’s vital to carry out a systematic troubleshooting process. Here are some repair strategies:

- Inspection and Diagnosis: Always begin with a thorough inspection. Check for visible wear and tear on couplings, seals, and bearings. Utilize vibration analysis and thermography to identify underlying issues.

- Coupling Alignment: If misalignment is detected, use a laser alignment tool to ensure the motor and pump shafts are correctly aligned to prevent vibrations that can lead to further damage.

- Bearing Replacement: Should you discover worn bearings, it’s crucial to replace them promptly. Ensure you use compatible bearings to maintain the pump’s efficiency.

- Seal Replacement: If leaks are present, replace worn seals with high-quality materials suited for the operating conditions of the pump.

- Clear Blockages: Regularly clean and inspect the pump’s intake and discharge for blockages, ensuring that fluid can flow freely.

- Address Cavitation: If cavitation is a recurring issue, evaluate the pump’s operation conditions and make necessary adjustments, such as increasing the inlet pressure or reducing the pump speed.

Preventative Maintenance Tips

Preventative maintenance is key to maximizing the lifespan and efficiency of split coupled pumps. Here are some tips:

- Regular Inspections: Schedule regular inspections to catch potential issues before they escalate into costly repairs.

- Lubrication: Ensure that all moving parts are properly lubricated according to manufacturer specifications.

- Monitor Operating Conditions: Keep an eye on temperature and pressure fluctuations that could impact pump performance.

- Keep Records: Maintain detailed records of maintenance activities, repairs, and inspections. This can help identify trends and recurring issues.

- Training and Awareness: Ensure that operators are trained on proper pump operation and maintenance practices.

Conclusion

Split coupled pumps are vital components in many industrial settings, but like any machinery, they require attentive care and timely repairs. By staying vigilant for common issues and adhering to a preventative maintenance regime, organizations can minimize downtime and enhance the longevity of their pumps. Remember, addressing problems early can save valuable time, resources, and prevent more significant concerns down the road. For complex repairs or persistent issues, don’t hesitate to consult with professional pump service experts who can provide specialized assistance.

Armstrong Pumps

Armstrong Pumps Bell & Gossett

Bell & Gossett Taco Pumps

Taco Pumps Goulds Water Technology

Goulds Water Technology Grundfos Pumps

Grundfos Pumps Wilo & Scot Pumps

Wilo & Scot Pumps Boilermag XT magnetic filter

Boilermag XT magnetic filter Hoffman Specialty

Hoffman Specialty John Crane

John Crane McDonnell & Miller

McDonnell & Miller Heat Exchangers

Heat Exchangers B&G Power Packs

B&G Power Packs Weg Motors

Weg Motors TechTop Motors

TechTop Motors US Motors & Nidec

US Motors & Nidec Baldor Motors

Baldor Motors SKF Motor Bearings

SKF Motor Bearings Motor Repairs

Motor Repairs