Understanding Centrifugal Pump Repairs in Surrey, BC

Centrifugal pumps are crucial components in various industries, from water treatment facilities to manufacturing plants. When these pumps fail or degrade in performance, it can lead to significant downtime and increased operational costs. For businesses in Surrey, BC, understanding the nuances of centrifugal pump repairs is essential for maintaining efficiency and minimizing disruptions.

What is a Centrifugal Pump?

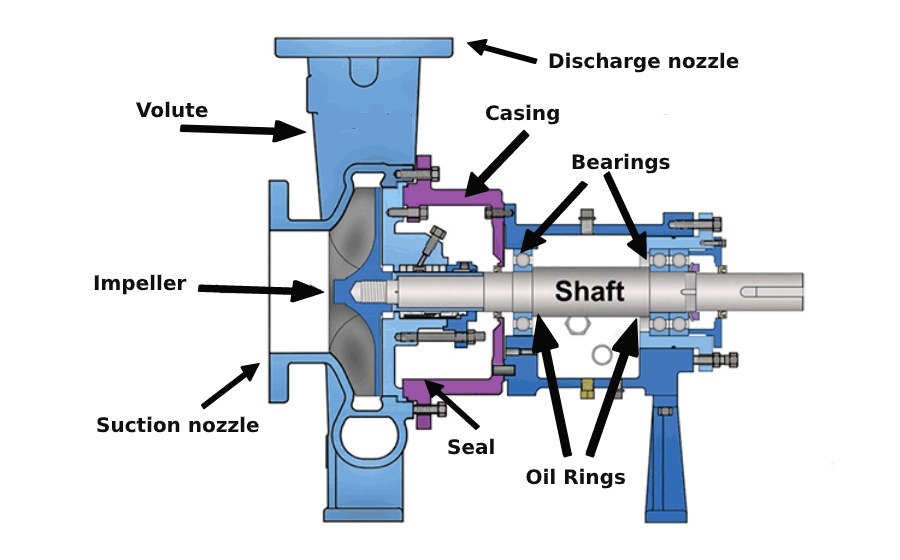

Before diving into repairs, let’s briefly discuss what a centrifugal pump is and how it works. Centrifugal pumps are mechanical devices that use rotational energy to move fluids. They consist of an impeller, a casing, and a shaft connected to a motor. The impeller creates a flow of liquid through centrifugal force, making these pumps ideal for handling large volumes of fluid at relatively low pressures.

Before diving into repairs, let’s briefly discuss what a centrifugal pump is and how it works. Centrifugal pumps are mechanical devices that use rotational energy to move fluids. They consist of an impeller, a casing, and a shaft connected to a motor. The impeller creates a flow of liquid through centrifugal force, making these pumps ideal for handling large volumes of fluid at relatively low pressures.

Common Issues with Centrifugal Pumps

Centrifugal pumps are subject to a variety of issues that may require repair:

- Cavitation: This occurs when vapor bubbles form in the pump and collapse, causing noise, vibration, and damage. It typically results from low inlet pressure or high temperature.

- Seal Failures: Mechanical seals can wear out over time, leading to leakage and potential environmental hazards.

- Impeller Damage: Debris in the fluid can cause pitting or breakage in the impeller, reducing efficiency.

- Bearing Wear: Bearings support the rotating shaft. Over time, they can wear down, leading to increased friction and overheating.

- Suction or Discharge Blockage: Blockages in the suction line or discharge valve can severely impact pump performance.

The Importance of Timely Repairs

Prompt attention to centrifugal pump issues can prevent minor problems from escalating into costly repairs or complete pump failures. Here are several reasons why timely repairs are crucial:

- Minimized Downtime: Quick repairs reduce the amount of time the pump is out of service, helping maintain production schedules.

- Cost Efficiency: Addressing small issues before they develop into major problems can save on repair costs and prevent the need for complete pump replacements.

- Extended Equipment Lifespan: Regular maintenance and timely repairs can significantly prolong the life of centrifugal pumps.

- Safety and Compliance: Leaking pumps can pose environmental hazards and safety risks. Regular maintenance ensures compliance with local regulations and safety standards.

Choosing a Repair Service in Surrey, BC

When selecting a pump repair service, consider the following factors:

- Experience and Expertise: Look for companies with proven experience in repairing centrifugal pumps and a solid reputation in the Surrey area.

- Range of Services: Choose a repair service that offers comprehensive solutions, including troubleshooting, parts replacement, and maintenance plans.

- Timeliness: Ensure that the service provider can respond quickly to minimize downtime.

- Customer Reviews: Check for customer testimonials and reviews to gauge the reliability and quality of their services.

- Certification and Compliance: Verify that the repair service adheres to industry standards and has the necessary certifications to operate in your region.

Preventive Maintenance Tips

To reduce the likelihood of needing repairs, consider implementing a preventive maintenance schedule for your centrifugal pumps:

- Regular Inspections: Schedule regular inspections to identify potential issues early.

- Routine Cleaning: Keep the pump and its surroundings clean to prevent debris from entering the system.

- Monitor Performance: Consistently monitor the pump’s performance metrics to detect changes that may indicate problems.

- Lubrication: Ensure that all moving parts are properly lubricated according to manufacturer specifications.

Conclusion

Centrifugal pump repairs are crucial for maintaining the efficiency and reliability of industrial operations in Surrey, BC. By understanding common issues, the importance of timely repairs, and choosing the right service provider, businesses can ensure that their pumps operate smoothly and effectively. Implementing preventive maintenance strategies will further enhance performance and extend the lifespan of centrifugal pumps. Regular attention will not only save costs but also contribute to overall operational success. Call Inline Sales & Services Ltd. in Surrey for all your pump repairs.

Armstrong Pumps

Armstrong Pumps Bell & Gossett

Bell & Gossett Taco Pumps

Taco Pumps Goulds Water Technology

Goulds Water Technology Grundfos Pumps

Grundfos Pumps Wilo & Scot Pumps

Wilo & Scot Pumps Boilermag XT magnetic filter

Boilermag XT magnetic filter Hoffman Specialty

Hoffman Specialty John Crane

John Crane McDonnell & Miller

McDonnell & Miller Heat Exchangers

Heat Exchangers B&G Power Packs

B&G Power Packs Weg Motors

Weg Motors TechTop Motors

TechTop Motors US Motors & Nidec

US Motors & Nidec Baldor Motors

Baldor Motors SKF Motor Bearings

SKF Motor Bearings Motor Repairs

Motor Repairs