Why Pump Service Matters

In commercial and industrial hydronic systems, downtime and inefficient performance aren’t just inconveniences — they’re costly. Failing pumps can lead to increased energy consumption, compromised comfort or process control, and unexpected service calls. That’s why timely repairs, right-sizing, and choosing the correct replacement components matter. When it comes to trusted brands, the name Bell & Gossett (B&G) has long been a benchmark.

And when it comes to getting those B&G parts from a reliable partner in Western Canada, Inline Sales & Service Ltd. in Surrey, BC offers a compelling combination of selection, expertise and local service.

Who is Inline Sales & Service Ltd.

Inline Sales & Service Ltd. has been serving commercial pump, motor and hydronic parts for over 30 years from their Surrey, BC location. They’re a local, independent specialist who doesn’t just sell stock items, but also offers skilled in-shop repairs, custom builds and full installation services. Inline Sales & Services Ltd.+2Inline Sales & Services Ltd.+2

Some of their key credentials and value-adds:

-

They list B&G among the major brands they support. Inline Sales & Services Ltd.

-

They are authorized B&G distributor for parts, pumps and warranty support in Canada. Inline Sales & Services Ltd.+1

-

They maintain both pump parts and the capability to repair or custom-build pumps on site. Inline Sales & Services Ltd.+1

-

Their website provides online shopping of many B&G parts, enabling easier procurement. Inline Sales & Services Ltd.

In short: you get local accessibility + brand authenticity + service capability.

The Part Ecosystem for Bell & Gossett Pumps

When you’re maintaining or repairing B&G pumps, being aware of the parts-ecosystem is essential. Inline Sales lists for B&G:

-

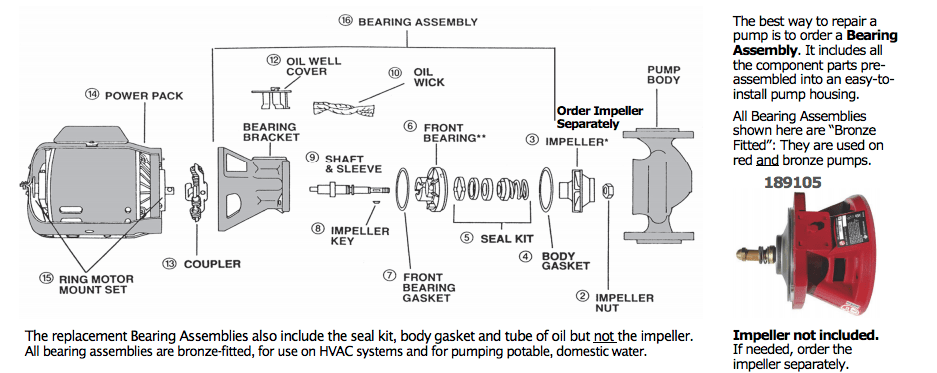

Bearing assemblies

-

Power-packs / motors

-

Couplers

-

Flanges & isolation flanges

-

Gaskets

-

Impellers

-

Mechanical seals

Inline Sales & Services Ltd.+1

Why these matter

-

Bearings & seals – Often the wear “weak points”. Failing bearings or mechanical seals leads to leaks, vibration, noise and ultimately failure.

-

Couplers & flanges – These enable the pump to interface properly with the piping system, allow removal/maintenance, isolation and safe servicing.

-

Impellers – If the performance drops, an under-sized or worn impeller might be the culprit; replacement restores flow/head.

-

Gaskets – Often overlooked, but leaking gaskets can reduce efficiency, lead to corrosion or short-life of pump internals.

Inline Sales, by maintaining a stock of these parts for B&G, means you can often get what you need quickly — reducing downtime.

Repair vs Replacement: Why Choose Repair

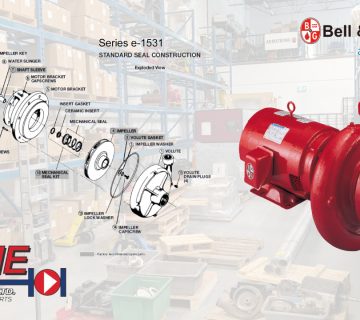

With pumps like the B&G Series E-80, E-90, E-1531 etc., you have the option of full replacement or rebuild/repair. Inline Sales helps with repair kits. For example, they list an “E-80/E-1531 1-1/4″ Repair Kit (145JM-215JM)” on their site. Inline Sales & Services Ltd.

Advantages of repair:

-

Cost-effective: Often significantly cheaper than full new pump.

-

Less downtime: Repairing parts can be quicker than re-engineering a replacement.

-

Sustainability: Reuse of the pump body or motor retains existing installation integrity (piping/mounting/etc).

-

Performance regain: Using correct OEM parts restores near-original performance.

Things to watch for:

-

Ensure you’re using genuine B&G parts (Inline is authorized).

-

If the pump is very old or its duty has changed, sometimes full replacement is wiser.

-

Always check compatibility: correct series, shaft size, impeller trim and service kit number. B&G’s parts catalogue is helpful. Xylem

Why Using Inline Sales & Service Matters Locally

Since you’re in Surrey / greater Vancouver area, working with a local distributor like Inline Sales offers benefits:

-

Quick access: Local inventory means shorter lead time, potentially same-day support.

-

On‐site service integration: They offer repair, install and parts support — not just “order parts online”.

-

Technical know-how: Their technicians are familiar with B&G systems, parts cross-reference and local HVAC/hydronic contexts.

-

Authenticity & warranty: As an authorized distributor, you reduce risk of counterfeit/incorrect parts and ensure manufacturer warranty support.

-

Custom builds: They even custom build B&G pumps and ship in as little as 2 days. Inline Sales & Services Ltd.+1

Practical Tips Before Ordering Parts

When you contact Inline Sales (or any parts supplier), here are some tips to streamline the process:

-

Identify pump series and model – E.g., B&G Series E-80, E-90, E-1531 etc. Inline’s site lists these specifically. Inline Sales & Services Ltd.

-

Record nameplate data – Shaft size, impeller size, motor HP, serial number.

-

Check for service-kit availability – Many repairs can be done via kits rather than full assemblies. Inline lists repair kits. Inline Sales & Services Ltd.

-

Confirm parts compatibility – Some parts may have changed revisions; make sure the parts match your pump’s revision/series.

-

Consider future spare parts – If you’re maintaining a fleet, it may be wise to stock critical spares (seals, gaskets, bearings) so you’re ready.

-

Evaluate cost vs full replacement – If the pump is very aged, burned out or application duty changed, compare repair cost + downtime vs. new pump.

-

Work with technicians – Inline’s service team can assist in the diagnosis and ensure correct parts are selected.

Real-World Example: Repairing a B&G E-80 Pump

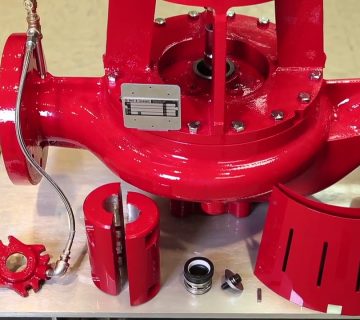

Let’s walk through a hypothetical: You have a B&G E-80 pump that’s showing vibration and leak at the mechanical seal. The shaft size is 1-1/4″, impeller is trimmed down.

-

You reach out to Inline Sales and identify the correct repair kit: “B&G E-80/E-1531 1-1/4″ Repair Kit (145JM-215JM)” listed. Inline Sales & Services Ltd.

-

The kit includes the mechanical seal, appropriate gaskets, & the shaft sleeve.

-

Their technicians inspect the pump, confirm no major damage to the housing or impeller.

-

The parts are shipped locally or picked up, the repair is done, the pump reinstalled with minimal downtime.

-

Result: Restored performance, reduced leak and vibration, extended life of the pump.

Summary

If you’re working with hydronic systems, HVAC or industrial pumping in the Vancouver/BC region, and you rely on B&G pumps, then Inline Sales & Service Ltd in Surrey is a local partner worth noting. They offer:

-

Authorized B&G parts distribution

-

A wide parts catalogue (flanges, seals, bearings, impellers, etc)

-

Service and repair capability

-

Custom pump build ability

-

Local, responsive support

By choosing the right parts, using authorized distributors, and working with capable technicians, you’ll maximize uptime, performance and cost‐effectiveness of your B&G pumping systems.

Armstrong Pumps

Armstrong Pumps Bell & Gossett

Bell & Gossett Taco Pumps

Taco Pumps Goulds Water Technology

Goulds Water Technology Grundfos Pumps

Grundfos Pumps Wilo & Scot Pumps

Wilo & Scot Pumps Boilermag XT magnetic filter

Boilermag XT magnetic filter Hoffman Specialty

Hoffman Specialty John Crane

John Crane McDonnell & Miller

McDonnell & Miller Heat Exchangers

Heat Exchangers B&G Power Packs

B&G Power Packs Weg Motors

Weg Motors TechTop Motors

TechTop Motors US Motors & Nidec

US Motors & Nidec Baldor Motors

Baldor Motors SKF Motor Bearings

SKF Motor Bearings Motor Repairs

Motor Repairs