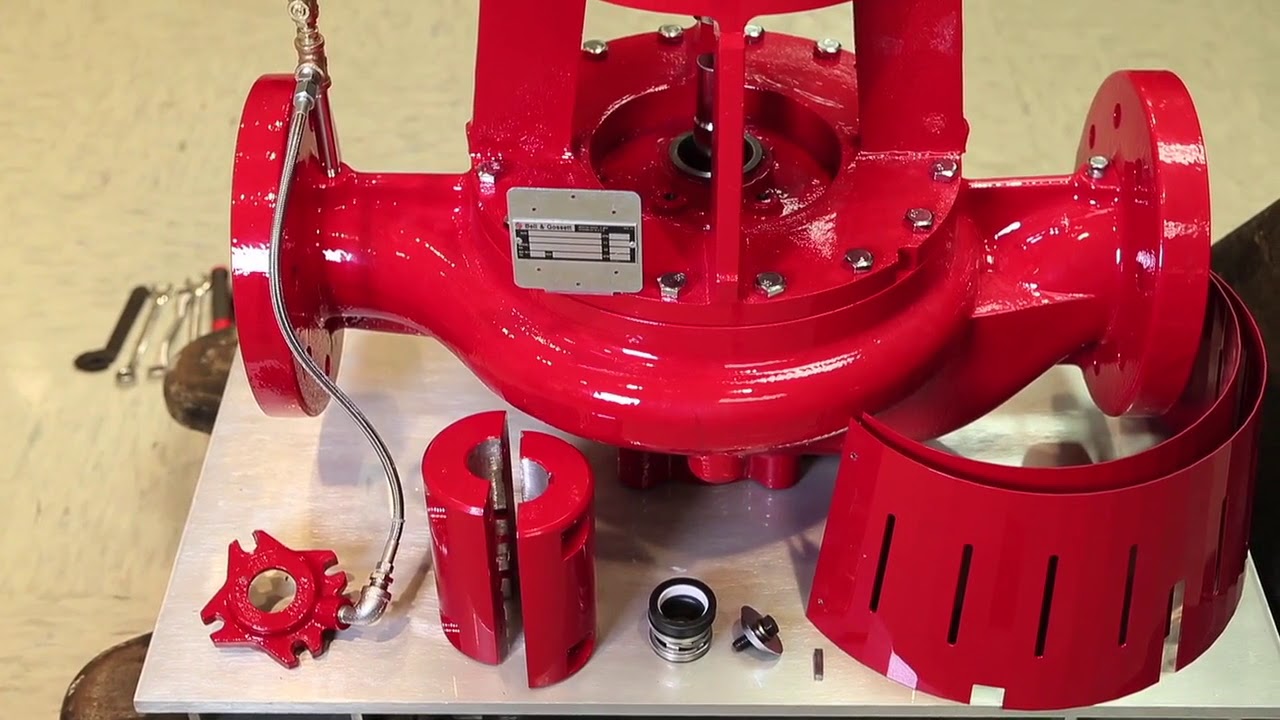

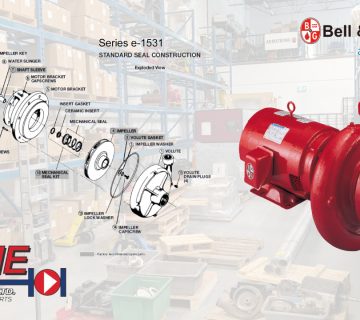

Building Bell & Gossett e-80 Pumps at Inline Sales (Surrey, BC)

How we assemble, test, and deliver hardworking in-line pumps for Lower Mainland projects—fast.

If you work on hydronic systems in Metro Vancouver, you’ve probably seen Bell & Gossett’s e-80 pumps on submittals and in mechanical rooms. At Inline Sales in Surrey, BC, we don’t just sell them—we build, test, and customize e-80 in-line pumps in-house so contractors get the right pump, on time, with the documentation they need to turn wrenches without surprises.

What is the e-80?

The Bell & Gossett e-80 is a compact, vertical in-line centrifugal pump commonly used for closed-loop HVAC applications—chilled water, hot water, glycol blends, and secondary/tertiary circuits. Its in-line configuration simplifies piping, reduces footprint, and makes maintenance straightforward. The design plays nicely with VFDs and modern BAS controls, and the service-friendly layout keeps downtime to a minimum.

Typical uses: hydronic heating/cooling loops, heat pump water circuits, fan coil/air handler distribution, and light commercial booster duties (where suitable).

How we build your e-80 at Inline Sales

We keep a focused inventory and an efficient bench process so we can turn around builds quickly and accurately. Here’s our standard flow:

-

Project Intake & Pump Selection

Send us your duty point (gpm/L/s and ft/psi head), fluid type/temperature, and system details. Our team runs the selection to match the performance curve, motor requirements, and connection size. We’ll flag efficiency opportunities and confirm compatibility with any VFD you plan to use. -

Bill of Materials & Pick

We stage the pump casing, impeller trim, motor, mechanical seal, wear rings (as applicable), flanges/grooved adapters, and any accessories (gauge cocks, P/T ports, suction diffusers, triples duty valves, etc.). Hardware is checked against the job number and submittal. -

Assembly & Fit-Up

On the bench, we set the impeller to the specified trim, verify rotation, and align the motor/pump stack according to manufacturer tolerances. Seal faces are handled and installed with care (clean, lint-free environment). We torque fasteners to spec and apply thread treatments where required. -

Bench Test & QC

Each build gets a rotation check, insulation resistance check on the motor, and a pressure/leak check of wetted joints. We complete a QC sheet that follows the pump to the site, noting serials, motor nameplate data, and seal type. -

Documentation & Delivery

You’ll receive the submittal package (cut sheets, performance point, wiring notes, and O&M), plus our QC record. We can coordinate delivery across the Lower Mainland or stage for pickup at our Surrey location.

Customization options we handle in-house

-

Motors & Controls:

Standard premium-efficiency motors, VFD-ready configurations, and BAS-friendly setups (terminal box orientation, leads). We can pair with your specified drive or provide recommendations. -

Mechanical Seals:

Standard carbon/ceramic seals for HVAC duty, with options for alternate faces and elastomers for glycol or elevated temperature service. -

Connections:

Flanged or grooved ends, with reducer sets where the pipe spec demands it. We also stock isolation valves, triple duty valves, and P/T ports to simplify commissioning. -

Materials & Coatings:

Factory coatings are standard; we can provide touch-up kits and advise on corrosion protection for coastal installations. -

Accessories:

Suction diffusers, check valves, spring isolators/inertia pads, and smart air vents—bundled and tagged to your pump skid.

Quality you can measure

Our Surrey shop follows a consistent QA checklist:

-

Verified duty point and impeller trim per selection

-

Motor rotation and insulation resistance recorded

-

Seal model, elastomer, and size logged

-

Nameplate data captured for BAS/VFD programming

-

All fasteners torqued to spec; all gaskets/seals inspected

-

Visual inspection: paint, lifting points, flange faces, guards

We keep records of every build, so if you call from site, we can pull your pump’s details in seconds.

Submittals & commissioning support

Need a clean submittal for consultants? We’ll package curves, dimensions, motor data, and wiring notes. On commissioning day, we can help with:

-

VFD ramp and minimum flow recommendations

-

Start-up venting and alignment checks

-

Differential pressure set-points for variable flow systems

-

Seal run-in best practices

Lead times & service

Because we assemble locally, we can respond quickly to change orders, emergency replacements, and punch-list surprises. If you need a like-for-like swap on an existing e-80, send us the nameplate photo and we’ll match it.

How to order (fastest path)

-

Email or call with your duty point, fluid, temperature, and connection size.

-

Share constraints (electrical service, VFD yes/no, flange/groove preference, any height/clearance limits).

-

Approve the selection and pricing we send back.

-

Schedule pickup or delivery—often same or next business day depending on configuration.

Sample specification text (drop into your notes)

Pump: Vertical in-line centrifugal, Bell & Gossett e-80 or equal, close-coupled, bronze-fitted, suitable for hydronic heating/cooling service.

Performance: ___ L/s at ___ kPa head (___ gpm at ___ ft).

Motor: ___ HP, ___ V, ___ PH, TEFC, premium efficiency, VFD-compatible.

Seal: Mechanical, carbon/ceramic faces with EPDM (or as scheduled).

Connections: ___ in. flanged (or grooved) with isolation valves and P/T ports.

Accessories: Triple duty valve, suction diffuser/strainer as scheduled.

Assembly & QA: Built and bench-checked by Inline Sales (Surrey, BC). Provide QC record, O&M, and nameplate data at turnover.

Why contractors choose Inline Sales (Surrey, BC)

-

Local builds, local accountability. You can talk to the actual tech who assembled your pump.

-

Speed without guesswork. Proper selection and documented QC cut down callbacks.

-

Parts on hand. Seals, flanges, valves, and common accessories under one roof.

-

Support after the sale. From VFD setup notes to replacement kits years later.

Ready to get your e-80 moving?

Send your duty point and job details, and we’ll take it from there. If you prefer, snap a photo of the existing nameplate and we’ll match it. We’re right here in Surrey—serving the Lower Mainland with pumps that are built right and built fast.

Armstrong Pumps

Armstrong Pumps Bell & Gossett

Bell & Gossett Taco Pumps

Taco Pumps Goulds Water Technology

Goulds Water Technology Grundfos Pumps

Grundfos Pumps Wilo & Scot Pumps

Wilo & Scot Pumps Boilermag XT magnetic filter

Boilermag XT magnetic filter Hoffman Specialty

Hoffman Specialty John Crane

John Crane McDonnell & Miller

McDonnell & Miller Heat Exchangers

Heat Exchangers B&G Power Packs

B&G Power Packs Weg Motors

Weg Motors TechTop Motors

TechTop Motors US Motors & Nidec

US Motors & Nidec Baldor Motors

Baldor Motors SKF Motor Bearings

SKF Motor Bearings Motor Repairs

Motor Repairs