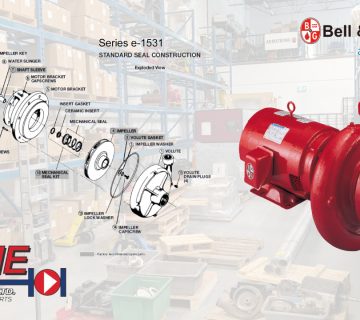

Bell & Gossett E-60 VS E-90 Pumps

Here’s a comparative blog-style deep dive into the Bell & Gossett e-60 vs e-90 series pumps. If you work with hydronic / HVAC pump selection, replacement, or maintenance, understanding how these two lines differ can help ensure you pick the best pump for your system.

Introduction

Bell & Gossett (a Xylem brand) manufactures several in-line centrifugal pumps for HVAC, potable water, and other clean fluid applications. Two of their newer lines are the e-60 and e-90 series. While they share many features and are both intended for high reliability and efficiency, each has design trade-offs and application sweet spots. Below I compare how they stack up in various dimensions:

Overview of Each Series

e-60

- Designed as a small flex-coupled in-line centrifugal pump. (Xylem)

- Used for heating, cooling, potable water, and other clean-water fluid transfer applications. (Xylem)

- Range: ~0.25 HP up to ~3 HP, motor at 1,750 RPM with various sizes / configs. (National Pump Supply)

- Available in multiple material configurations: bronze-fitted, all bronze, etc. (National Pump Supply)

e-90

- Close-coupled, in-line centrifugal pump line. (Close-coupled meaning the pump and motor are integrated, without a separate coupling and bearing frame). (Xylem)

- Targeted for small commercial HVAC and similar applications. (Xylem)

- Better for applications needing compact installs, simpler maintenance in tight spaces, or where the motor-pump assembly benefit outweighs the flexibility of a flex-coupled design. (National Pump Supply)

Key Differences

Here are the major points of distinction:

| Feature | e-60 | e-90 |

|---|---|---|

| Pump-Motor Coupling / Design | Flex-coupled (three-piece) design: separate pump, coupling, motor; allows servicing without removing piping in many cases. (Xylem) | Close-coupled design: motor and pump are integrated; no separate bearing frame. More compact; less mechanical complexity in couplings. (Xylem) |

| Ease of Maintenance / Serviceability | e-60: three-piece design + “internally self-flushing, unitized mechanical seal” makes seal replacement and impeller/motor work more straightforward. Bearings are permanently lubricated. (National Pump Supply) | e-90: designed to be easy to maintain via back-pull-out (in many cases), has option for ECM (electronically commutated) motors which have quieter operation, less vibration, possibly longer life. Also uses unitized mechanical seals. (Xylem) |

| Efficiency & Motor Options | Good hydraulic efficiency; range of motor sizes, but generally standard induction motors. (National Pump Supply) | Offers higher-efficiency options, especially with ECM motor variants. Quieter, lower vibration. (Xylem) |

| Space / Footprint & Mounting Flexibility | Because of flex-coupled design, possibly larger footprint; more components. Requires space for the coupling and for accessing mechanical parts. | More compact due to close coupled design. Can be mounted horizontally or vertically. Better suited where space is constrained. (Xylem) |

| Pressure, Temp, Performance Range | e-60 covers many clean-water, heating/cooling tasks; size range up to 3 HP; adequate for many residential/commercial systems. (AF Supply) | The e-90 line supports higher pressures (some models up to ~175 psi) and a broader temp range. Good for more demanding small-commercial applications. (National Pump Supply) |

| Cost & Complexity | Possibly simpler and lower cost to manufacture; more parts but more standard components. More work to install / align / service due to coupling. | Potentially higher cost per pump (especially ECM motor versions), but savings in reduced maintenance, smaller space, and less complexity in alignment. |

Pros & Cons: When Each Is Best

When you might pick e-60

- If you need high flexibility in servicing: being able to pull the pump apart, replace seal/impeller without disturbing piping.

- If the system is larger or less constrained by space, so flex-coupled layout is acceptable or even preferable for long life.

- Where cost of initial equipment matters – maybe standard induction motors suffice.

- When you have existing systems that already use (or are designed for) e-60 / legacy Series 60 dimensions: the e-60 is dimensionally interchangeable with the older Series 60. (AF Supply)

When e-90 is the better choice

- When space is tight and you want a compact install.

- For commercial HVAC systems needing higher pressures or temperature ranges.

- If noise, vibration, and efficiency are important; especially with ECM motor options.

- Where minimal alignment or coupling maintenance overhead is desired.

- In new installations where the benefits of a close-coupled design can be fully realized (less complexity, fewer parts).

Practical Considerations & Trade-Offs

- Repair vs Replace: e-60 might be easier/cheaper to repair in the field because parts (coupling, impeller, seal) are more accessible and modular. e-90 may have fewer moving external components, but if something in the integrated motor-pump fails, the replacement part may be more specialized.

- Operating Efficiency over Time: ECM motors (available in e-90) often reduce energy consumption, especially in partial-load operation. If the pump runs often and under varying loads, this difference can add up significantly.

- Installation Costs and Labor: For e-60, alignment of coupling, ensuring correct coupling shaft length, that kind of work is needed. e-90 may reduce some of those labor costs due to the close coupling.

- Spare Parts Availability: Because e-60 has been designed to match older Series 60 dimensions, parts may be more widely available or familiar to technicians. e-90 being newer and with more variants (e.g. bronze, all bronze, ECM) may require sourcing specific parts.

Conclusion

In sum:

- Both the e-60 and e-90 are high-quality lines from Bell & Gossett.

- If your project values modularity, ease of service, and aligns with existing legacy gear, e-60 may be the more “safe” choice.

- If you’re designing a new system where space, efficiency, and maintenance economy over time are priorities, e-90 likely offers better long-term ROI.

Here are some side-by-side spec-sheet numbers and dimension data for common sizes of the Bell & Gossett e-60 vs e-90 pumps, where available; followed by highlights of what the specs imply. (Specs from the manufacturers’ submitted data, but always double-check the exact model you’re using.)

Spec Sheet Snapshots

| Model / Size | Suction & Discharge Size | Motor HP | Max RPM / Motor Type | Flow & Head Range* | Max Working Pressure | Temp Range | Approx Dimension Notes / Footprint |

|---|---|---|---|---|---|---|---|

| e-60 — 1.25×1.25×5.25 | 1.25″ NPT | ~½ HP | 1725 RPM induction motor, also ECM versions | From data in ECM version: ~60 GPM (depending on impeller) / ~25 ft head for small models (e650-series etc.) (Pump Products) | 175 psi (12 bar) (Xylem) | −20 °F to +250 °F (varies with seal materials) (Xylem) | The 1.25×1.25×5.25 model: overall pump body plus motor bracket length (“A”, “B”, etc.) ~ around 7-8 inches motor bracket height max, overall lengths ~ around 16.5-18 in depending on HP/motor. (Xylem) |

| e-60 — 1.5×1.5×7 (flex coupled) | 1.5″ NPT | ~¾-1 HP | 1750 RPM motors (standard induction) (Xylem) | Flow/head per the “1.5×1.5×7” spec sheet: flow rates up to somewhere in the neighborhood of what the curve shows for that size (depends impeller trimming). Example head up to ~60-70 ft in some trims for that size. (Xylem) | 175 psi (Xylem) | Same temp range (seal material dependent) (Xylem) | Larger size, heavier; dimension “L” (length between suction & discharge flange faces), etc. ~23.6 in for full assembly in some versions. (Xylem) |

| e-90 — standard close-coupled, 1″ through 3″ | 1″ to 3″ connections (flange or companion flanges) (Xylem) | ¼-5 HP depending on size / model; ECM versions for smaller HP’s (½-1 HP) in single phase. (Xylem) | 1725 RPM for standard motors; ECM/variable speed for ECM options, some motors allow variable speed down to ~350 RPM on applicable models. (Xylem) | Hydraulic coverage: 20 GPM to 250 GPM (≈4.5 m³/hr to 56.8 m³/hr). Head can reach up to what is needed depending on model — in many cases heads up toward ~200+ ft depending on HP and impeller. (Xylem) | Also up to 175 psi (12 bar) working pressure. (Xylem) | Temp range: −10 °F to +250 °F (≈ −23 to +121 °C) for many models. (Xylem) | Because close-coupled, usually more compact in overall length vs similarly rated flex-coupled pumps; back-pull-out design helps with maintenance. Example for 1.5″/1 HP close-coupled: length “A” ~7.5-7.5 in bracket height, “B” (length) ~16-18 in or so depending on phase. (Xylem) |

* “Flow & Head Range” depends heavily on impeller size, speed, and trim. These are approximate for standard configurations.

Comparison Insights from the Numbers

From those spec snapshots, some conclusions / useful comparisons:

- Pressure Rating: Both e-60 and e-90 are built for ~175 psi (12 bar) max working pressure. So in that regard, they are similar, and either could be suitable for relatively high pressure/hydronic systems. (Xylem)

- Temperature Capability: Again similar in the higher-end for many models (~250 °F) depending on seal materials. The e-60 sometimes shows a slightly broader lower end or different options depending on seal choice. (Xylem)

- Flow / Head Coverage: The e-90 has greater maximum flow (up to ~250 GPM) than most standard e-60 models. If you need higher flow and modest to high head, the e-90 gives more range. The e-60 tends to cover smaller flows / heads (though depending on size you can push it). (Xylem)

- Dimensional / Footprint Differences: For same connection sizes, e-90 tends to have more compact length in many cases since the motor is close-coupled. For flex-coupled e-60 you have coupling components which add length and complexity. Also weight will be higher in equivalent HP, or at least bulkier in e-60 flex designs.

- Motor / Speed Variation: Both have options with variable speed / ECM in smaller sizes. But for e-90, ECM / “smart motor” versions seem more common in ½-1 HP sizes, with greater flow coverage. e-60 offers ECM for many of its smaller sizes too. The ability to go down in speed gives you more efficiency and flexibility under partial load. (Xylem)

Armstrong Pumps

Armstrong Pumps Bell & Gossett

Bell & Gossett Taco Pumps

Taco Pumps Goulds Water Technology

Goulds Water Technology Grundfos Pumps

Grundfos Pumps Wilo & Scot Pumps

Wilo & Scot Pumps Boilermag XT magnetic filter

Boilermag XT magnetic filter Hoffman Specialty

Hoffman Specialty John Crane

John Crane McDonnell & Miller

McDonnell & Miller Heat Exchangers

Heat Exchangers B&G Power Packs

B&G Power Packs Weg Motors

Weg Motors TechTop Motors

TechTop Motors US Motors & Nidec

US Motors & Nidec Baldor Motors

Baldor Motors SKF Motor Bearings

SKF Motor Bearings Motor Repairs

Motor Repairs