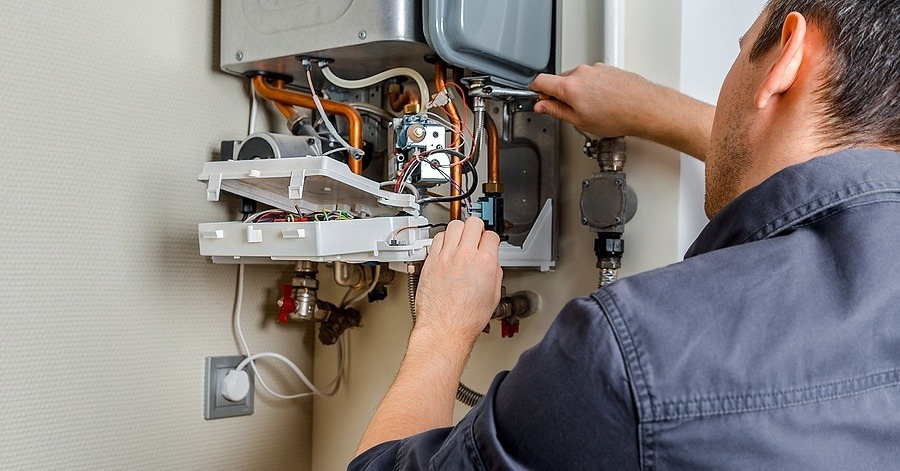

Don’t Wait for Your Equipment to Fail! 10 Things that Should Be a Part of Your Annual Boiler Inspection

Because boilers and heating systems have so much opportunity for cost and energy savings, your annual boiler inspection should be your favorite time of the year. Not only is it a chance to identify and perform critical maintenance on your boiler, but it’s also a chance to ensure your system is operating at maximum efficiency – saving you potentially thousands of dollars each year.

Boilers are significant energy users at most commercial and industrial facilities, so an excellent preventive maintenance program that includes annual inspection is essential and, in most states, required by law. Left unattended, problems such as leaks and corrosion can build up over time, leading to energy losses of up to 20%. Proper maintenance and operational practices can help to ensure optimal performance, therefore reducing operating costs while increasing your equipment life. It is highly recommended that a qualified boiler technician perform all inspections and maintenance to ensure quality.

Annual boiler inspections are typically done in the summer to ensure that any repairs or replacements of system components can be completed before those cold winter months begin to settle in. However, annual inspections do not negate the need for regular equipment checkups. Check out our blog post 5 things you should be checking on your boiler DAILY for more information.

The following essential elements should be a part of the annual inspection and cleaning of a boiler:

Inspect and clean the fireside.

The fireside consists of surfaces inside the boiler exposed to water and hot gases. Check for signs of ash and soot accumulation, warping, and leaks. The fireside should appear as clean as possible. A dirty fireside such as one with deposits of soot or non-combustible material will lead to a loss of efficiency.

Inspect and clean the waterside.

The waterside is the inside surface of any boiler component that contains water or steam. Typically, this includes inspection of boiler drums, drum internals, visible parts of the tubes, tube connections, water walls superheaters, and fittings. This inspection should not begin until the boiler has cooled to 120F or 90F to avoid the possibility of scalding.

Inspect economizers, deaerators, blow-down tanks, and condensate receivers.

Check for signs of leaks, deterioration, build-up, or corrosion. If there is evidence of these issues, the equipment should be cleaned, repaired, or replaced following the manufacturer’s recommendations.

Check the refractory

Boiler failures are often caused by cracking or erosion in the refractory. Therefore, refractory repair is done typically every six months or semi-annually. Patch refractory as necessary following the manufacturer’s recommendations.

Burner Inspection

Open the burner and inspect the components. Clean all components to like-new condition and ensure that there are no leaks and connections are tight.

Detach controls and inspect them for proper operation

Reinstall and double-check to ensure the controls are operational and set at an appropriate safe set point before restarting the boiler.

Check the fluid levels on hydraulic valves

Check the fluid levels and inspect the hydraulic valves for any sign of leakage. Repair any leaks immediately to ensure system stability and efficiency.

Check all filter elements

Filters keep unwanted materials out of your system, so they must stay clean and free of contamination. As a part of your annual boiler inspection, the filters should be cleaned or replaced as needed. On “self-cleaning” filters, double-check that impurities are flushed from the filter body.

Check boiler feedwater and recirculation pumps.

Most instances of significant boiler damage are caused by low-water or contaminated feedwater. Inspections will indicate the effectiveness of the system’s feedwater treatment program. If there is evidence of untreated or incorrectly treated feedwater, turn to a feedwater consultant to determine the system’s water treatment needs. Replace or recondition elements as necessary and according to the manufacturer’s recommendations.

Empty and wash out condensate receivers and make an internal inspection.

Condensate receivers capture valuable moisture and send it back to the boiler to be reused. If working correctly, the system will have improved energy efficiency and cost substantially less to operate. An annual boiler inspection should involve emptying and washing out the receivers and an internal assessment. If the receiver has a mounted make-up valve, it should be overhauled and checked for proper operation.

Check electrical connections on starters and relays.

Connections may become loose due to vibration from shipping or operation. Make sure all connections are tight, and the electrical equipment is clean. Failure to maintain the electrical equipment is the most common cause of nuisance maintenance problems.

Boiler operation is compromised if there are signs of overheating, excessive scale, corrosion, or damaged pressure vessel components. The inspector’s job is to identify and repair any of these conditions. If an outside inspector is checking your facility’s boiler, some preliminary steps should be taken before the inspector’s arrival. If you need help preparing for the boiler inspector’s arrival, check out our post 14 things you need to do before the boiler inspector arrives.

Failure to properly maintain your boiler is a great way to waste money and increase the likelihood of dangerous malfunctions. So, stay safe and save money by getting that boiler inspected! The team at Inline Sales & Service has the skills to maintain and repair your boilers. Our in shop team can repair pumps and our warehouse is stocked with parts that you need.

Armstrong Pumps

Armstrong Pumps Bell & Gossett

Bell & Gossett Taco Pumps

Taco Pumps Goulds Water Technology

Goulds Water Technology Grundfos Pumps

Grundfos Pumps Wilo & Scot Pumps

Wilo & Scot Pumps Boilermag XT magnetic filter

Boilermag XT magnetic filter Hoffman Specialty

Hoffman Specialty John Crane

John Crane McDonnell & Miller

McDonnell & Miller Heat Exchangers

Heat Exchangers B&G Power Packs

B&G Power Packs Weg Motors

Weg Motors TechTop Motors

TechTop Motors US Motors & Nidec

US Motors & Nidec Baldor Motors

Baldor Motors SKF Motor Bearings

SKF Motor Bearings Motor Repairs

Motor Repairs All Products

All Products Armstrong Pumps & Parts

Armstrong Pumps & Parts Booster Circulators

Booster Circulators Grundfos Pumps & Parts

Grundfos Pumps & Parts Hoffman Specialty Parts

Hoffman Specialty Parts Hydronic Specialty Parts

Hydronic Specialty Parts Goulds

Goulds All B&G Parts

All B&G Parts Air Vents & Separators

Air Vents & Separators B&G Inline E-60 Pump

B&G Inline E-60 Pump B&G Inline E-80 Pump

B&G Inline E-80 Pump B&G Inline E-90 Pump

B&G Inline E-90 Pump B&G End Suction E-1510 Pump

B&G End Suction E-1510 Pump B&G End Suction E-1531 Pump

B&G End Suction E-1531 Pump Ecocirc Pumps

Ecocirc Pumps Bearing Assemblies

Bearing Assemblies Power Packs (Motors)

Power Packs (Motors) Couplers

Couplers Flanges

Flanges Gaskets

Gaskets Impellers

Impellers Mechanical Seals

Mechanical Seals Bell & Gossett

Bell & Gossett Grundfos

Grundfos